WEAVING, TAILORING & FELTING

WEAVING

In Tibet, spinning and weaving was mostly the work of farmers who had the winter months in their houses to busy themselves with tasks other than agriculture. They spun lambs wool and wove it into narrow lengths of fine, dense fabric on back strap looms. Some areas in Lhokha, in southern Tibet, were famous for their woolen fabrics, producing such rare and expensive material it was available only as items that one purchased once in a lifetime and passed on as heirloom. Nomads catered to their own needs, spinning and weaving sheep wool that farmers considered coarse and unrefined. For this reason, Amdo nomads had little base to work from, beyond a natural inclination for spinning and weaving. From such a relatively clean slate, we were able to wholly create a textile industry, if on a small scale, in Amdo.

TAILORING

Until 20 years ago, there was very little cash economy in rural Tibet and nomads made everything they owned and wore, occasionally bartering meat and butter for flour or cotton cloth. Men and women sewed their heavy chubas, shirts, hats and boots as well as tents and storage bags for tsampa and cheese.

Eleven women and one man work in the tailoring section, which opened in 2012. Women find the ability to stitch a finished piece on their own empowering, a way to link skills they learned from their mothers to contemporary designs and forms. Working with precious fabrics must be accompanied with a strong attention to detail. The sewing, whether machine or hand must be perfect and quality control rigorous.

Most of the Norlha tailors have experience in hand sewing and their talent combined with the detailed work of our finished pieces lends them a timeless quality. Norlha’s tailors adapted their skill to the high variety of Norlha’s product scope ; felt toys, items of traditional or contemporary clothing, and a full range of monk’s robes. Their skills in hand sewing bring a new dimension to our carefully finished products.

FELTING

Felting is an ancient craft, a way of binding fibres to form fabrics and rugs for everyday use. It was highly developed among nomadic populations in Central Asia and the Caucasus where pieces over two thousand years old have been found. Among the nomads of Central Asia, felt, which is waterproof, provided shelter in the form of tents, clothing and rugs, many of which were intricately ornamented. As in all nomadic communities, felting was a part of daily existence in Ritoma, where all women learned to felt the wool they sheared from their sheep, making mats for sitting and sleeping, boots, raincoats and hats.

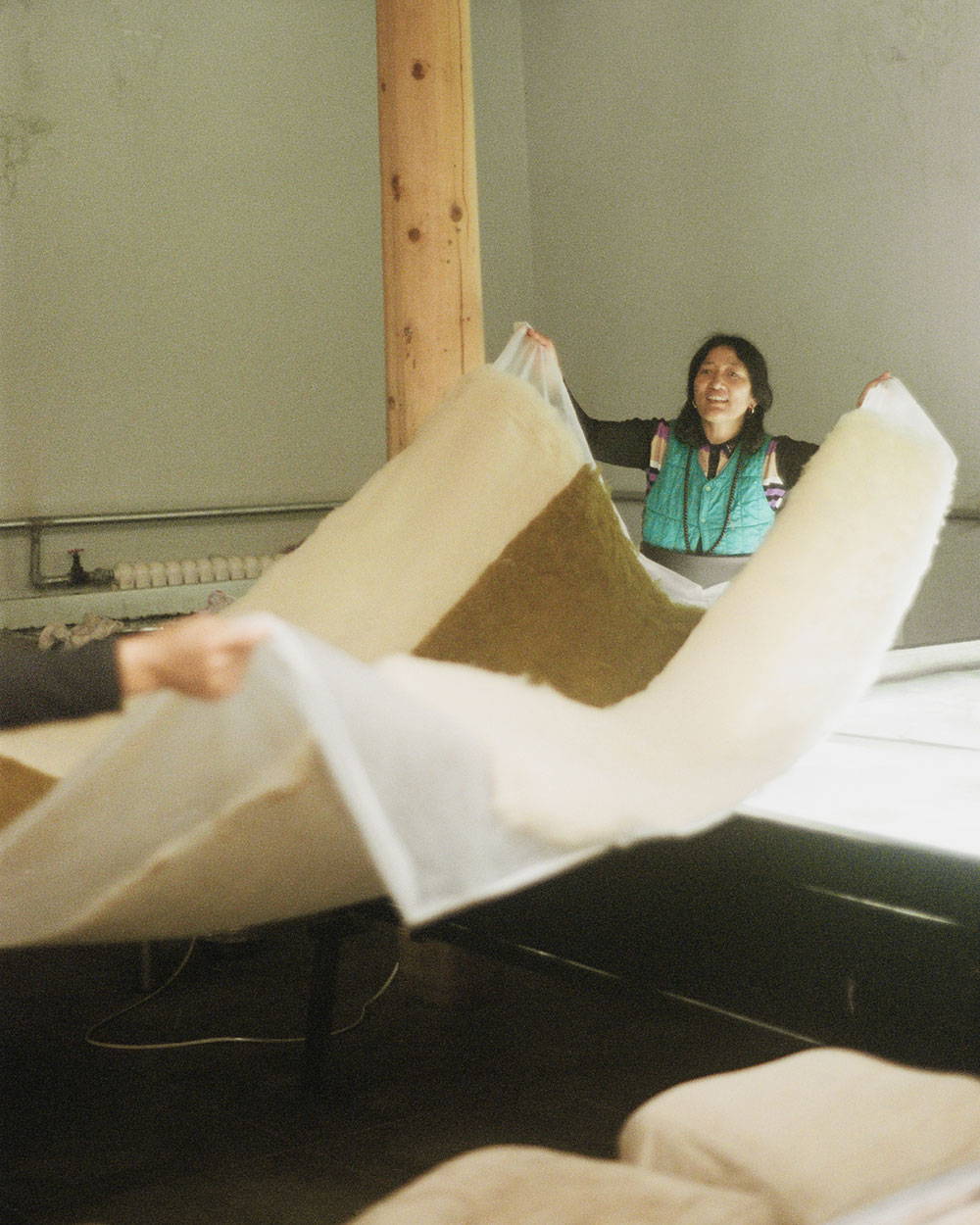

Norlha is first in creating products from felted yak khullu. We trusted the innate qualities of this fibre and felt that with some innovation we could transform this soft, luscious fibre into a new concept in interiors. After some research and experimentation, we realiSed that by combining modern machinery with hand techniques we could achieve exceptional results. Felting lends itself to a wide range of products. It is a complex process that begins with the pre-dyeing of the fibre, then relies on the expert hands of the women to lay out the design and even out the fibre to obtain a perfectly even piece. An intricate piece can take three women up to one day to complete.

Norlha felts in a number of thicknesses, each adapted to a particular use; wear, throws, or soft furnishings. Our fabrics range from heavy to light, from up to 800gr to our most noteworthy achievement of a lightweight 200gr backed in cotton cloth for stability. Sixteen women felt at Norlha. All of them were nomads as some point in their lives, and their long experience and ingenuity with hand felting coupled help from innovative technology made it possible to create the first felted yak khullu products for the home; contemporary in look, unique to the touch, soft and long lasting.